Process characteristics of die-casting aluminum parts

- Categories:Aluminum alloy shell

- Author:

- Origin:

- Time of issue:2022-11-30 16:37

- Views:

Process characteristics of die-casting aluminum parts

- Categories:Aluminum alloy shell

- Author:

- Origin:

- Time of issue:2022-11-30 16:37

- Views:

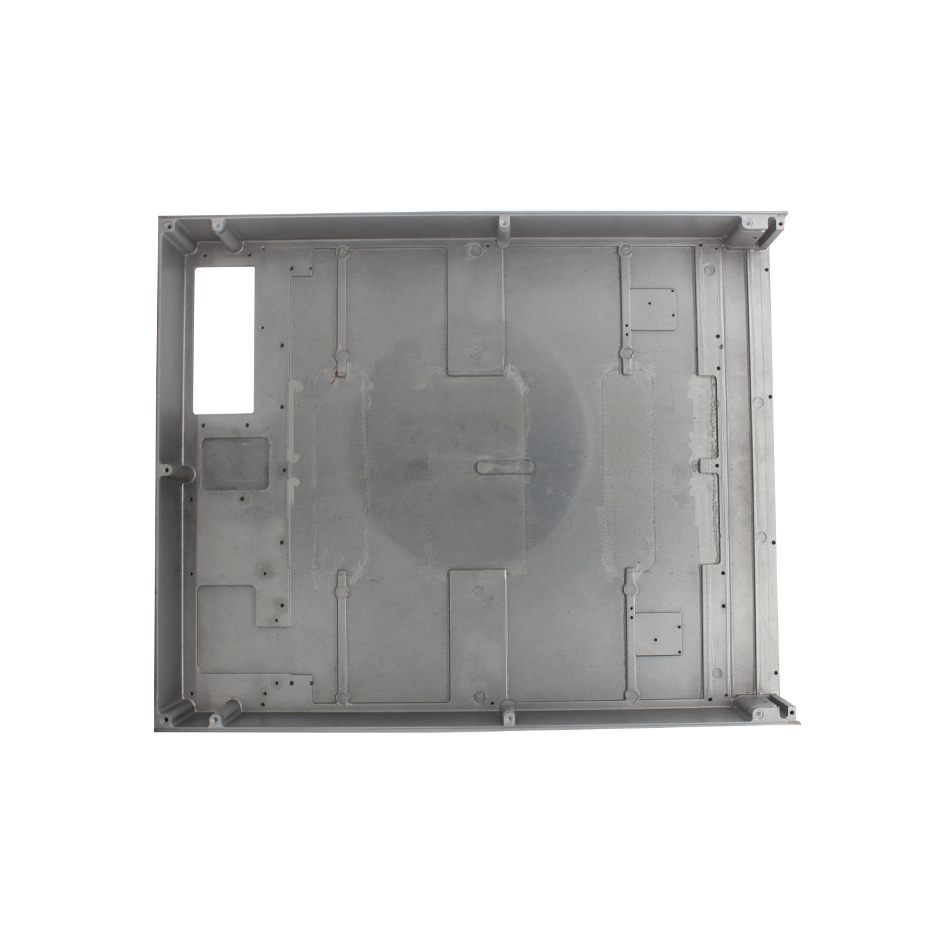

1. Good product quality: high dimensional accuracy of castings, generally equivalent to grade 6~7, even up to grade 4; good surface finish, generally equivalent to grade 5~8; high strength and hardness, generally 25% stronger than sand casting ~30%, but the elongation is reduced by about 70%; Dimensional stability, good interchangeability; Die-cast aluminum thin-wall complex castings. For example, the minimum wall thickness of zinc alloy die-casting aluminum parts can reach 0.3mm; aluminum alloy castings can reach 0.5mm; the minimum casting hole diameter is 0.7mm; the minimum pitch is 0.75mm.

2. High production efficiency: high machine productivity. For example, the domestic JⅢ3 horizontal cold air die-casting aluminum machine can die-cast aluminum 600-700 times in eight hours on average, and the small hot-chamber die-casting aluminum machine can die-cast aluminum 3000-7000 times in eight hours on average; The die-casting aluminum mold has a long service life. A pair of die-casting aluminum molds and die-casting aluminum clock alloys can last hundreds of thousands of times, or even millions of times; it is easy to realize mechanization and automation.

3. Excellent economic effect: due to the advantages of accurate size of die-casting aluminum parts and smooth surface. Generally, it is used directly without mechanical processing, or the processing amount is very small, so it not only improves the metal utilization rate, but also reduces a lot of processing equipment and man-hours; the casting price is cheap; combined die-casting aluminum and other metal or non-metal materials can be used .

推荐新闻

Foshan Nanhai Jiawei metal products Co., Ltd

Contact information:18928682636(Miss Liang)/18928682621(Mr. Tang)

Company phone:0757-85103282

Company fax:0757-85103183

Company email:sunny@nhjiawei.com / jia_tangvic@163.com

Marketing Center: No.90, hongganglihe Road, Lishui Town, Nanhai District, Foshan City

Production base: b3-1, zone 3, Enping Industrial Park, Jiangmen industrial transfer park (Enping Guangen profile Co., Ltd.)