How to repair the scratch of the aluminum alloy shell

- Categories:Aluminum alloy shell

- Author:

- Origin:

- Time of issue:2022-08-26 15:45

- Views:

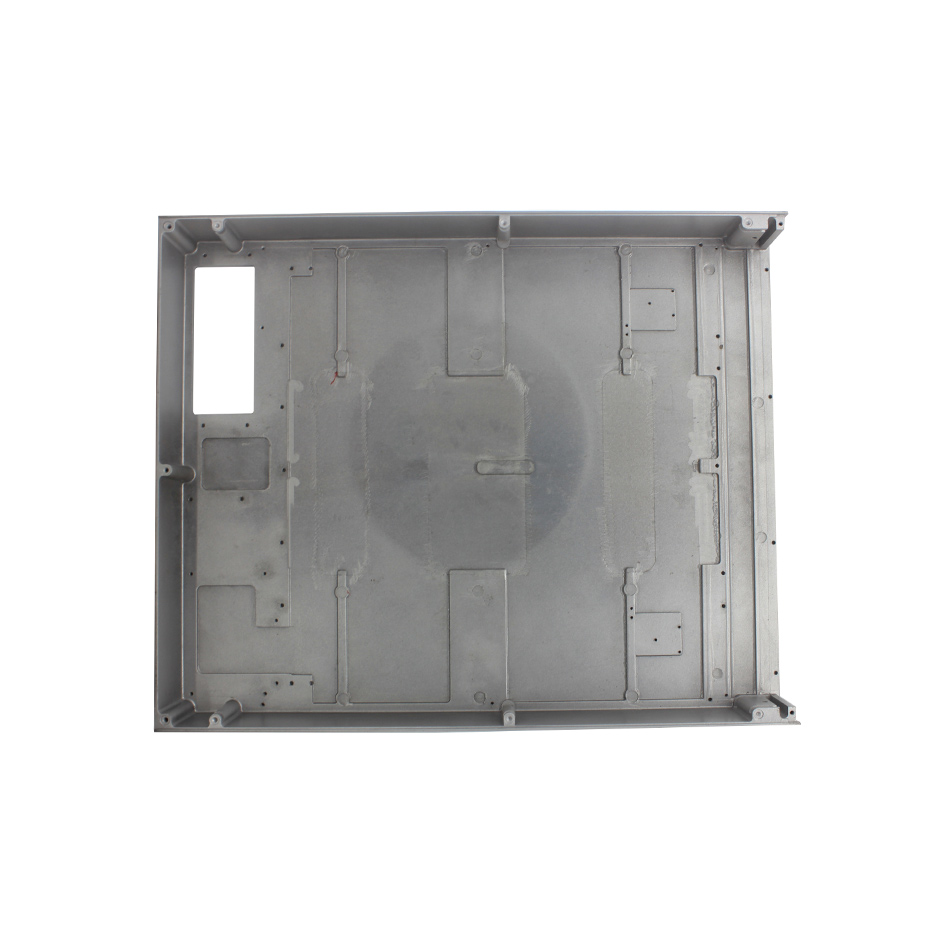

How to repair the scratch of the aluminum alloy shell

- Categories:Aluminum alloy shell

- Author:

- Origin:

- Time of issue:2022-08-26 15:45

- Views:

1. Due to the improper design of the stamping die: the pressure injury caused by the die itself; the die is too tight, the parts need to be pryed, and the gap caused by the prying.

Solution: Enterprises must improve the quality of mold repair, and aluminum shell molds must be regularly nitrided and the nitriding process must be strictly implemented. Strictly control the quality of the chemical composition of the ingot; improve the quality of mold repair, improve the precision of mold manufacturing and regular nitriding of the mold and strictly implement the nitriding process parameters.

2. Bumps during stamping and CNC processing: improper operation, the aluminum alloy shell touches the mold fixture, machine tool equipment, etc. when the part is taken; Alloy casing dropped.

Solution: Arrange the profiles reasonably in the material frame to avoid friction with each other as much as possible. In the production process of the aluminum casing, it should be handled with care to avoid scratches caused by human factors.

3. Bumps and scratches during the circulation of each process: improper stacking and collapse; the aluminum alloy casing is vigorously held; there are debris in the packaging material of the aluminum alloy casing. During the transfer process, the debris and the product friction cause scratches .

Solution: Use soft felt and plastic strips to separate the aluminum alloy shell from the profile and the auxiliary equipment to reduce the friction between them and cause damage. Clean the working belts such as the discharge track and the swing bed in time to avoid debris affecting the production and processing quality of the aluminum casing.

推荐新闻

Foshan Nanhai Jiawei metal products Co., Ltd

Contact information:18928682636(Miss Liang)/18928682621(Mr. Tang)

Company phone:0757-85103282

Company fax:0757-85103183

Company email:sunny@nhjiawei.com / jia_tangvic@163.com

Marketing Center: No.90, hongganglihe Road, Lishui Town, Nanhai District, Foshan City

Production base: b3-1, zone 3, Enping Industrial Park, Jiangmen industrial transfer park (Enping Guangen profile Co., Ltd.)